smt assembly hardness tester fabrication|Mastering SMT Assembly: Your Guide to Precision and Efficiency : distributor SMT assembly provides an alternative to the through-hole technique of PCB manufacturing, which saw its golden age in the 1970s and 1980s. As the electronics manufacturing sector evolved, a more efficient process became imperative—SMT assembly materialized from this necessity. SMT assembly for PCBs is an incredibly versatile process.

Resultado da 2 de ago. de 2023 · Menu Principote valoriza experiência gastronômica no Principote a preço fixo. O Princepote, Beach Club e Restaurante na Praia .

{plog:ftitle_list}

webSky Vegas is the ultimate destination for new, exclusive, and exciting online slots. Download the Sky Vegas App and enjoy exclusive games and the .

Step into the world of precision and innovation with our deep dive into SMT Assembly in PCB manufacturing. Uncover insights and strategies that are shaping the future .

This blog explains critical terms related to SMT assembly and reveals every detail of the SMT manufacturing process. SMT manufacturing is a standardized process in electronics contract manufacturing, but a lot of . Some potential defects that can occur in SMT assembly include: Soldering Defects. Insufficient solder – Caused by low solder volume or poor wetting.; Shorts – Excess solder bridges pads or components.; Solder balls – .Merit Assembly SMT assembly lines offer the finest production, with the best quality product for your contract manufacturing needs. Dedicated SMT operators and totally automated assembly lines offer innovative solutions to ensure . As the core technology used in modern electronics manufacturing, surface-mount technology (SMT) assembly density is increasing, the number of pins is increasing, and the pitch is decreasing. .

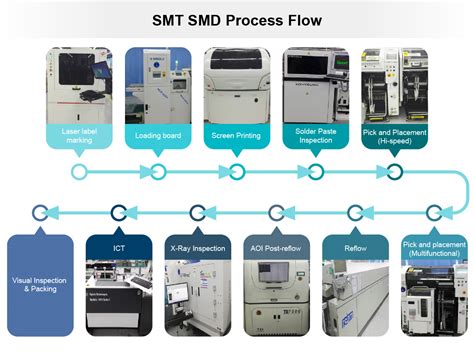

SMT assembly provides an alternative to the through-hole technique of PCB manufacturing, which saw its golden age in the 1970s and 1980s. As the electronics manufacturing sector evolved, a more efficient process became imperative—SMT assembly materialized from this necessity. SMT assembly for PCBs is an incredibly versatile process. The rest of this comprehensive guide will explore the SMT assembly process in detail. SMT Assembly Process Step-by-Step. The typical SMT assembly process involves the following key steps: 1. SMT Stencil Design and Fabrication. A stencil is a thin metal sheet laser cut with apertures matching the pads on the PCB.

What is the SMT Manufacturing Process [Step by

The assembly contains PCB, SMT, wound components and taking anywhere from 60 grams to over 1 kilo and the volumes estimated would require an automated dispensing process. It was also identified that labour was at a premium so an automated process would assist to keep the cost per unit down ensuring a quick and efficient production process.Printed Circuit Board Testing. By offering an extensive range of testing options, we work to ensure boards are fully functional and identify issues with non-functional or failed designs. Capabilities include: Functional testing; FICT testing (TAKAYA Flying Probe Tester) Board and system-level testing; RF performance to specification (frequency .Surface mount technology (SMT) has revolutionized the electronics manufacturing industry over the past few decades. The SMT assembly line, commonly known as the SMT line, allows for automated mass production of printed circuit board (PCB) assemblies with great precision and speed.. This article provides a comprehensive overview of SMT lines, how they work, costs, .

Surface Mount PCB Assembly. SMT is a flexible and powerful assembly process that has allowed manufacturers to produce modern devices with ever-smaller footprints. . we can assist with product prototyping and testing, contract manufacturing and more. Read on for details or contact our office directly to request a quote. Get Started Today .Detailed description With only 30 minutes to wait for the smt-860 automatic testing machine, which can automatically determine the production direction of the smt-860 automatic testing machine. SMT first article tester can automatically i. Shenzhen Future Technology Co., Ltd. In this article, we will specifically talk about SMT PCB assembly, including the definition of SMT manufacturing and the step-by-step guide for the SMT manufacturing process in electronics production. What is SMT Manufacturing. SMT means surface mount technology. SMT components are very small size packages like 0201,0402, TSSOP, DFN, QFN, QFP, etc.In addition to dedicated radio products, Rexon Technology also provides OEM / ODM services for PCBAs namely from SMT manufacturing of PCB process to product assembly provide one-stop service. Rexon is a high-quality PCB Assembly OEM / ODM / SMT / DIP Services, SMT / DIP Services - Factory manufacturer from Taiwan since 1990. In 2009, Rexon starts the new .

To adapt to such a trend, engineers adopt the SMT assembly/SMT manufacturing method. When some people look at the printed circuit boards with components of electronic products (smartphones, computers, medical electronics, telecommunication electronics, car electric parts, etc.), they may wonder how these components are mounted on the boards.

In regards to test fixture manufacturing, nothing has to change because Bead Probes are handled . SN 63 = 12.8 HV: Hardness 1 (soft) SAC 305 = 17.7 HV: Hardness 2 (middle) Innolot = 33.6 HV: Hardness 3 (hard) 9 . The solution to most contacting problems • aggressive Steel Tip . Less test probes After board assembly is completed The Surface Mount Technology (SMT) line, also known as the Surface Mount Assembly line or Surface Mount Production line, is a manufacturing process used in the electronics industry to assemble .PCB ASSEMBLY SERVICES PCB Assembly Express is an electronic manufacturing services (EMS) provider located in Tualatin, Oregon. We offer a variety of services including design, assembly and testing. Our state-of-the . So for better efficiency, most SMT manufacturing is done through automated assembly machines, especially when production is large scale.[2] SMT components are significantly smaller than through-hole components, .

Surface mount technology (SMT) revolutionized the electronics assembly industry by enabling the manufacture of smaller, lighter, and more reliable products. SMT production lines feature state-of-the-art equipment for high-speed component placement and soldering. However, without proper planning and optimization, even the most advanced SMT lines will underperform.Explore the world of SMT assembly with our comprehensive guide. Learn about surface mount technology processes, components, equipment, and applications across industries. Gain insights into SMT's advantages, challenges, best practices, environmental impact, and future trends shaping this crucial technology in electronics manufacturing.

If you're interested in the electronics industry, you've probably come across the term "PCB SMT assembly process" at some point. SMT, or surface mount technology, is a widely used method of assembling printed circuit boards (PCBs) that involves mounting electronic components directly onto the surface of the PCB without through-holes. New SMT Equipment: solder and mask and hardness (38) Soldering Microscopes and Magnifiers . DOE for Process Validation Involving Numerous Assembly Materials and Test Methods. . (CIT) courses recognize individuals as qualified trainers in the area of design, fabrication and inspection of rigid printed boards and prepare them to deliver .JWC Manufacturing Services Inc. . GXHB 3000 Digital Brinell Hardness Tester Usage Range The Brinell hardness test that shows the largest indentation among all the hardness tests is able to reflect the comprehensive features of the material, and the test is unaffected by the organ . SMT & PCB Assembly Forum Ask a Question. These boards often feature components with pin pitches smaller than 0.65mm. and maintaining high accuracy especially for QFPs with a pitch as tight as 0.5mm. To ensure the precision of SMT processing, we conclude with tips for FPC assembly that guarantee the high quality of FPC assembly.

SMT, EMS & PCB manufacturing companies. SMT, PCB Manufacturing Companies in Malaysia . WINTECH provides new/used/pre-owned SMT, AI & PCB Assembly (PCBA) equipment of various brands. Also supply service, modification & original or local-made spare parts. . We trade used test & measurement instrument such as brand Agilent/HP,Tektronix .

We ensure that all PCB manufacturing and assembly products are compliant and safe. . We are an intelligent manufacturer of one-stop rapid production from R & D, PCB design, PCB manufacturing, PCB assembly, PCBA test, finished product assembly, and cable harness. . which include prototype PCB assembly (free assembly fee for the 1st prototype . Gold fingers are those small gold-plated contacts along the edge of printed circuit boards that allow detachable connections for add-on cards and memory modules in computers and other devices. With the right design and manufacturing, gold fingers can provide reliable connectivity and stand up to thousands of insertion cycles.

Choose from hardness tester products, companies, forum discussions and technical articles - over 460 results. . New SMT Equipment: hardness tester (289) Hioki 1220 In-Circuit Tester. New Equipment . New Equipment | Assembly Services.

What Is SMT Assembly?

30 abril | 22:00. + INFO. Animação e Espetáculos no Casino .

smt assembly hardness tester fabrication|Mastering SMT Assembly: Your Guide to Precision and Efficiency